1:Chengdu Fengke Precision Tool Co Ltd,.located in the city of wood

industrial park in Chengdu, China. Fengke Tool specialized in the

R&D production and import-export trading of Tungsten Carbide

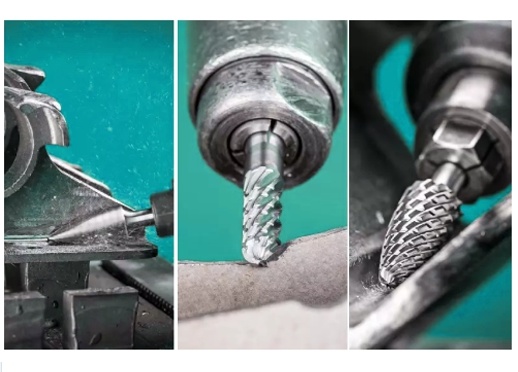

Cutting tools over 20 years.

Including woodworking,cutting fiber, metal cutting, packaging

cutting and construction machinery tools, which are widely used in

wood furniture manufacturing, metal cutting, construction

machinery, paper packaging.In the 20,000-square-meter plant , over

100 staffs work here.The annual product capacity amount is

10,000,000 -20,000,000,the products sell well in over 100 countries

and regions.

2:Excellence derives wholesome administration system and strict

inspection measure.

Fengke Tool has invested project management system and information

management system to make information sharing,accurate and fast,so

as to improve management efficiency.

3:Committed to be manufacturing more intelligently, Fengke Tool

possesses over 100 advanced equipment,develops more than 50

different standard products and hundreds of customized items.

The advanced measuring instruments have guaranteed that outstanding

quality of products,for appearance,dimension,mechanical performance

function,precision,wear resistance and hardness of new products

R&D in the factory.

4:Talented experts and creative professionals who have over 20

years experience in this field joined our R&D department

.Fengke Tool always boasts of its capable teams, specializing

respectively in business production and after sales service.